Cyfleuster o'r radd flaenaf yn cynnig gwasanaethau torri proffiliau metel dalen a dur manwl gywir

Manylion Cynnyrch

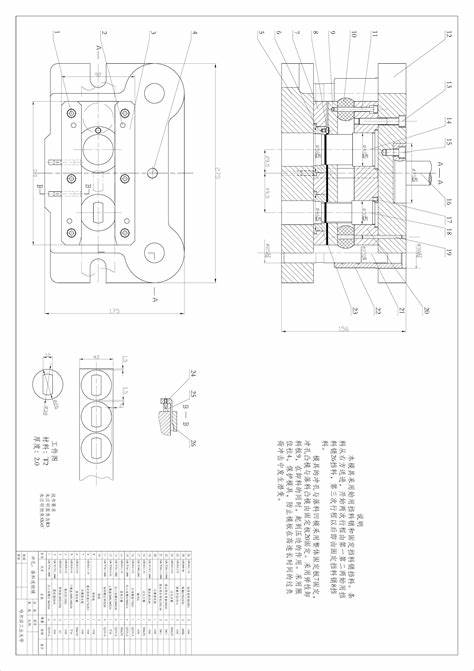

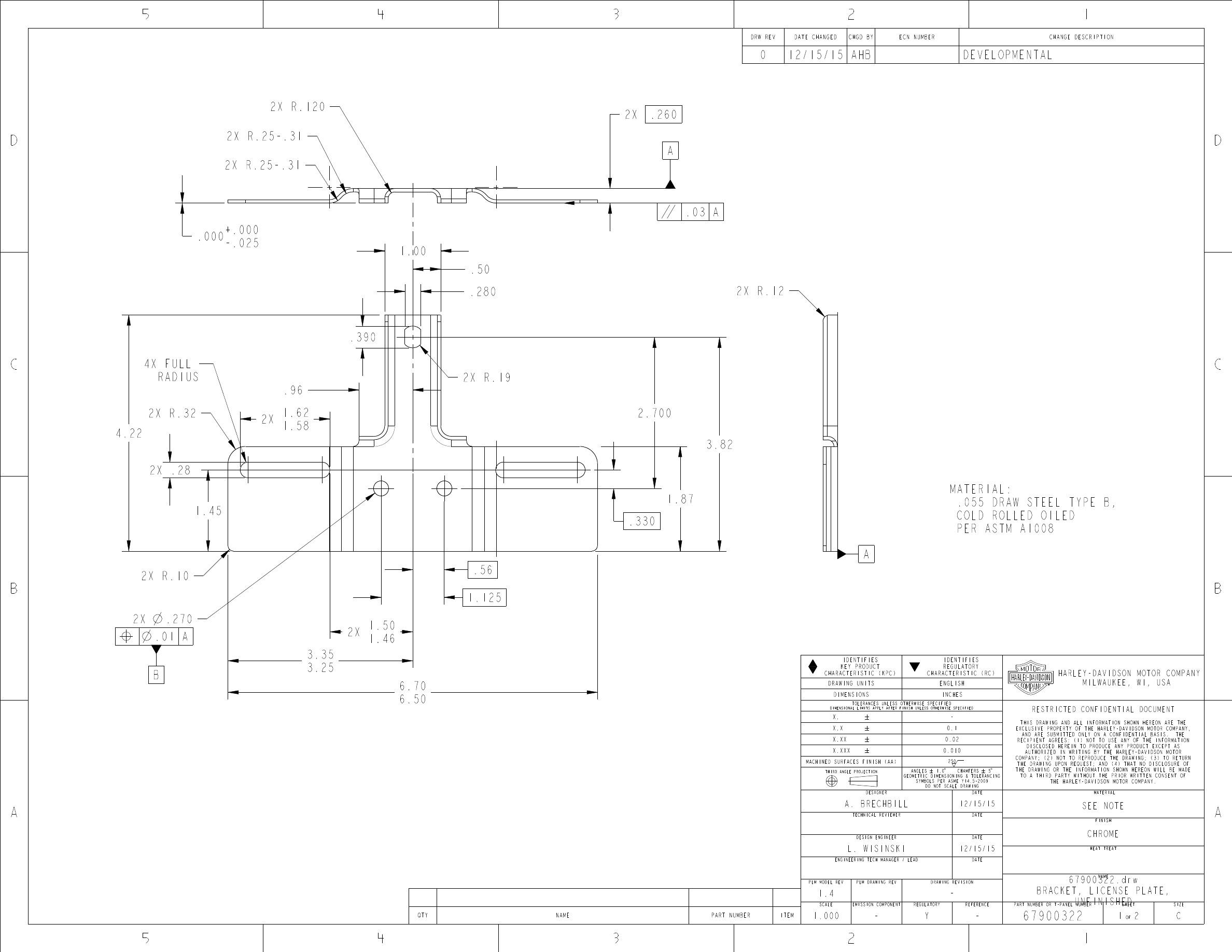

Mae rhannau wedi'u prosesu â dur yn seiliedig ar ddeunyddiau crai dur, yn ôl y lluniadau cynnyrch a ddarperir gan gwsmeriaid, mowldiau cynhyrchu cynnyrch wedi'u haddasu a'u cynhyrchu ar gyfer cwsmeriaid yn unol â'r manylebau cynnyrch gofynnol, dimensiynau, deunyddiau, triniaeth arwyneb arbennig, a gwybodaeth arall am y rhannau wedi'u prosesu. Cynhelir cynhyrchu manwl gywir, o ansawdd uchel, ac uwch-dechnoleg yn unol â gofynion y cwsmer. Os nad oes lluniadau dylunio, mae'n iawn. Bydd ein dylunwyr cynnyrch yn dylunio yn unol ag anghenion y cwsmer.

Y prif fathau o rannau wedi'u prosesu:

rhannau wedi'u weldio, cynhyrchion tyllog, rhannau wedi'u gorchuddio, rhannau wedi'u plygu,torri metel dalen

dalen fetel wedi'i thorri â laserMae ganddo'r nodweddion canlynol: Yn gyntaf, mae ganddo ystod eang o gymwysiadau a gall dorri amrywiol ddefnyddiau fel metelau, deunyddiau nad ydynt yn fetelau, a deunyddiau cyfansawdd heb gynhyrchu parthau yr effeithir arnynt gan wres a pharthau dirywiad. Mae'n addas ar gyfer prosesu manwl gywir amrywiol ddefnyddiau. Yn ail, nid oes angen defnyddio cemegau yn ystod y broses dorri, mae'n gyfeillgar i'r amgylchedd, yn ddiwenwyn ac yn ddiniwed, ac yn bodloni gofynion diogelu'r amgylchedd gwyrdd gweithgynhyrchu modern. Yn ogystal, gall torri jet dŵr gyflawni torri manwl gywir o ansawdd uchel gydag arwynebau torri llyfn heb yr angen am brosesu eilaidd, gan arbed costau cynhyrchu.

Defnyddir torri jet dŵr yn helaeth mewn awyrofod, gweithgynhyrchu ceir, deunyddiau adeiladu a meysydd eraill. Ym maes awyrofod, gellir defnyddio torri jet dŵr i dorri rhannau awyrennau, fel ffiselaj, adenydd, ac ati, gan sicrhau cywirdeb ac ansawdd rhannau. Mewn gweithgynhyrchu ceir, gellir defnyddio torri jet dŵr i dorri paneli corff, rhannau siasi, ac ati, gan sicrhau cywirdeb ac ansawdd ymddangosiad y rhannau. Ym maes deunyddiau adeiladu, gellir defnyddio torri jet dŵr i dorri marmor, gwenithfaen a deunyddiau eraill i gyflawni cerfio a thorri mân.

Yn fyr, mae gan dorri jet dŵr, fel technoleg torri a phrosesu effeithlon, ecogyfeillgar, a manwl gywir, ragolygon cymhwysiad eang a galw yn y farchnad, a bydd yn chwarae rhan bwysig yn y diwydiant gweithgynhyrchu yn y dyfodol.

| Personoltorri dur ysgafnRhannau Gwneuthuriad Metel Dalen Manwl | ||||

| Dyfynbris | Yn ôl eich llun (maint, deunydd, trwch, cynnwys prosesu, a thechnoleg ofynnol, ac ati) | |||

| Deunydd | Dur carbon, dur di-staen, SPCc, SGCc, pibell, galfanedig | |||

| Prosesu | Torri laser, plygu, rhybedu, drilio, weldio, ffurfio metel dalen, cydosod, ac ati. | |||

| Triniaeth Arwyneb | Brwsio, Sgleinio, Anodizing, Gorchuddio Powdwr, Platio, | |||

| Goddefgarwch | '+/-0.2mm, archwiliad ansawdd QC 100% cyn ei ddanfon, gall ddarparu ffurflen archwilio ansawdd | |||

| Logo | Argraffu sidan, Marcio laser | |||

| Maint/Lliw | Yn derbyn meintiau/lliwiau personol | |||

| Fformat Lluniadu | .DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.Draft | |||

| Amser Darllen Sampl | Negodi amser dosbarthu yn ôl eich anghenion | |||

| Pacio | Trwy carton/crât neu yn ôl eich gofyniad | |||

| Tystysgrif | ISO9001: SGS/TUV/ROHS | |||

Enghreifftio

| Rhannau Peiriannu wedi'u Haddasu | |

| 1. Maint | Wedi'i addasu |

| 2. Safonol: | Wedi'i addasu neu GB |

| 3. Deunydd | Wedi'i addasu |

| 4. Lleoliad ein ffatri | Tianjin, Tsieina |

| 5. Defnydd: | Bodloni anghenion cwsmeriaid eu hunain |

| 6. Gorchudd: | Wedi'i addasu |

| 7. Techneg: | Wedi'i addasu |

| 8. Math: | Wedi'i addasu |

| 9. Siâp yr Adran: | Wedi'i addasu |

| 10. Arolygiad: | Archwiliad gan gleient neu archwiliad gan drydydd parti. |

| 11. Dosbarthu: | Cynhwysydd, Llong Swmp. |

| 12. Ynglŷn â'n Ansawdd: | 1) Dim difrod, dim plygu 2) Dimensiynau cywir 3) Gellir gwirio'r holl nwyddau gan drydydd parti cyn eu cludo |

O ran torri metel, mae sawl dull y gellir eu defnyddio, yn dibynnu ar y math o fetel a'r canlyniad a ddymunir. Mae rhai o'r prosesau torri mwyaf cyffredin yn cynnwys torri laser, torri plasma, torri jet dŵr, a chneifio. Mae torri laser yn ddelfrydol ar gyfer cyflawni toriadau manwl gywir a chymhleth, tra bod torri plasma yn fwyaf addas ar gyfer torri trwy ddalennau metel trwchus. Mae torri jet dŵr yn opsiwn amlbwrpas a all dorri trwy ystod eang o ddefnyddiau, ac mae cneifio yn ddull cost-effeithiol ar gyfer torri llinellau syth ar ddalen fetel.

Wrth ddewis gwasanaeth torri metel, mae'n bwysig ystyried gofynion penodol eich prosiect. P'un a oes angen i chidalen ddur wedi'i thorri, dur meddal, neu fathau eraill o fetel, chwiliwch am ddarparwr gwasanaeth sydd â'r arbenigedd a'r offer i ymdrin â'ch anghenion penodol. Ystyriwch ffactorau fel trwch y metel, cymhlethdod y toriadau, a'r gorffeniad a ddymunir ar gyfer ymylon y toriad.

Yn ogystal, mae'n bwysig dewisgwasanaeth torri metelsy'n blaenoriaethu cywirdeb, ansawdd ac effeithlonrwydd. Chwiliwch am ddarparwr sy'n defnyddio technoleg torri uwch ac sydd â hanes o gyflawni canlyniadau o ansawdd uchel. Mae hefyd yn fuddiol dewis gwasanaeth sy'n cynnig gwasanaethau ychwanegol fel cynhyrchu metel, gorffen a chydosod, i symleiddio'r broses gynhyrchu a sicrhau datrysiad di-dor o'r dechrau i'r diwedd.

Arddangosfa Cynnyrch Gorffenedig

Pecynnu a Llongau

Mae pecynnu a chludo rhannau wedi'u torri â jet dŵr yn rhan bwysig o sicrhau ansawdd cynnyrch a danfoniad diogel. Yn gyntaf oll, ar gyfer rhannau torri â jet dŵr, oherwydd eu harwyneb torri llyfn a'u manylder uchel, mae angen dewis deunyddiau a dulliau pecynnu priodol i atal difrod yn ystod cludiant. Ar gyfer rhannau bachgwasanaeth torri laser metel, gellir eu pacio mewn blychau ewyn neu gartonau. Ar gyfer rhannau torri jet dŵr mawr, fel arfer mae angen eu pacio mewn blychau pren i sicrhau nad ydynt yn cael eu difrodi yn ystod cludiant.

Yn ystod y broses becynnu, dylid gosod a llenwi'r rhannau torri jet dŵr yn rhesymol yn ôl nodweddion y rhannau torri jet dŵr er mwyn atal difrod a achosir gan wrthdrawiad a dirgryniad yn ystod cludiant. Ar gyfer rhannau wedi'u torri â jet dŵr gyda siapiau arbennig, mae angen dylunio atebion pecynnu wedi'u teilwra hefyd i sicrhau eu bod yn aros yn sefydlog yn ystod cludiant.

Yn ystod y broses gludo, dylid dewis partner logisteg dibynadwy i sicrhau y gellir danfon y rhannau torri jet dŵr i'r gyrchfan yn ddiogel ac yn amserol. Ar gyfer cludiant rhyngwladol, mae angen i chi hefyd ddeall y rheoliadau mewnforio perthnasol a safonau cludiant y wlad gyrchfan i sicrhau clirio tollau a danfon llyfn.

Yn ogystal, ar gyfer rhai rhannau torri jet dŵr wedi'u gwneud o ddeunyddiau arbennig neu siapiau cymhleth, mae angen rhoi sylw i ofynion arbennig fel gwrthsefyll lleithder a gwrth-cyrydiad wrth becynnu a chludo er mwyn sicrhau nad yw ansawdd y cynnyrch yn cael ei effeithio.

I grynhoi, mae pecynnu a chludo rhannau torri jet dŵr yn gysylltiadau pwysig i sicrhau ansawdd cynnyrch a boddhad cwsmeriaid. Mae angen cynllunio a gweithredu'n rhesymol o ran dewis deunydd pecynnu, llenwi sefydlog, dewis cludiant, ac ati er mwyn sicrhau diogelwch a chyfanrwydd y cynnyrch a'i ddanfon i gwsmeriaid yn brydlon.

CRYFDER Y CWMNI

Wedi'i wneud yn Tsieina, gwasanaeth o'r radd flaenaf, ansawdd arloesol, byd-enwog

1. Effaith graddfa: Mae gan ein cwmni gadwyn gyflenwi fawr a ffatri ddur fawr, gan gyflawni effeithiau graddfa mewn cludiant a chaffael, a dod yn gwmni dur sy'n integreiddio cynhyrchu a gwasanaethau

2. Amrywiaeth cynnyrch: Amrywiaeth cynnyrch, gellir prynu unrhyw ddur rydych chi ei eisiau gennym ni, yn bennaf yn ymwneud â strwythurau dur, rheiliau dur, pentyrrau dalennau dur, cromfachau ffotofoltäig, dur sianel, coiliau dur silicon a chynhyrchion eraill, sy'n ei gwneud hi'n fwy hyblyg Dewiswch y math o gynnyrch a ddymunir i ddiwallu gwahanol anghenion.

3. Cyflenwad sefydlog: Gall cael llinell gynhyrchu a chadwyn gyflenwi fwy sefydlog ddarparu cyflenwad mwy dibynadwy. Mae hyn yn arbennig o bwysig i brynwyr sydd angen symiau mawr o ddur.

4. Dylanwad brand: Cael dylanwad brand uwch a marchnad fwy

5. Gwasanaeth: Cwmni dur mawr sy'n integreiddio addasu, cludo a chynhyrchu

6. Cystadleurwydd prisiau: pris rhesymol

CWSMERIAID YN YMWELD

Cwestiynau Cyffredin

1. Sut alla i gael dyfynbris gennych chi?

Gallwch adael neges i ni, a byddwn yn ateb pob neges mewn pryd.

2. A fyddwch chi'n danfon y nwyddau mewn pryd?

Ydym, rydym yn addo darparu cynhyrchion o'r ansawdd gorau a'u danfon ar amser. Gonestrwydd yw egwyddor ein cwmni.

3. A allaf gael samplau cyn archebu?

Ydw, wrth gwrs. Fel arfer mae ein samplau am ddim, gallwn gynhyrchu yn ôl eich samplau neu luniadau technegol.

4. Beth yw eich telerau talu?

Ein tymor talu arferol yw blaendal o 30%, a'r gweddill yn erbyn B/L.

5. Ydych chi'n derbyn yr arolygiad trydydd parti?

Ydw, yn bendant, rydym yn derbyn.

6. Sut ydym ni'n ymddiried yn eich cwmni?

Rydym yn arbenigo mewn busnes dur ers blynyddoedd fel cyflenwr aur, mae ein pencadlys wedi'i leoli yn nhalaith Tianjin, croeso i ymchwilio mewn unrhyw ffordd, bob tro.